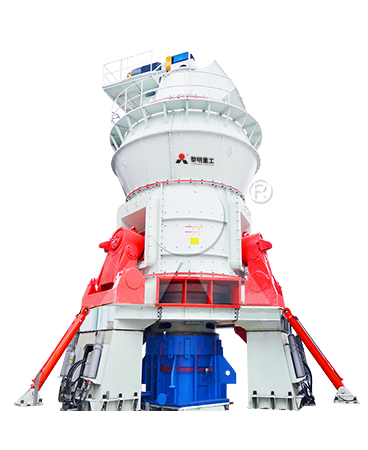

Processed Materials:

-

Bentonite grinding and processing

-

POP and gypsum board plant

-

Quartz Stone Grinding Mill

-

Dolomite Grinding Mill

Applications:

limestone desulfurization in power plant, heavy calcium carbonate processing, non-metallic mineral powder making, solid fuel grinding, building materials and chemical industry.

Capacity: 3-55TPH

Input size: 30-50mm

Performance Advantages

Mature technology and stable Performance: 4th generation mill, more than 30 years of mill manufacturing experience. Bevel gear overall drive provides strong power. the production capacity increased by 20% under the same power condition.

Economical and reliable: can grind a variety of minerals to meet the needs of different specifications of particle size; low investment cost, low operating cost, single machine processing capacity up to 60T/H.

Low cost, less maintenance: Patented technology, with Inner automatic thin-oil lubricating system, long oil change cycle, low frequency, low cost.

Scientific allocation, low energy consumption: Adjustable output size, efficient powder production. The vulnerable parts adopt special technology and material, more wear-resistant.

Environmental protection: unique air recycling system, together with advanced dust collector make environment much cleaner.

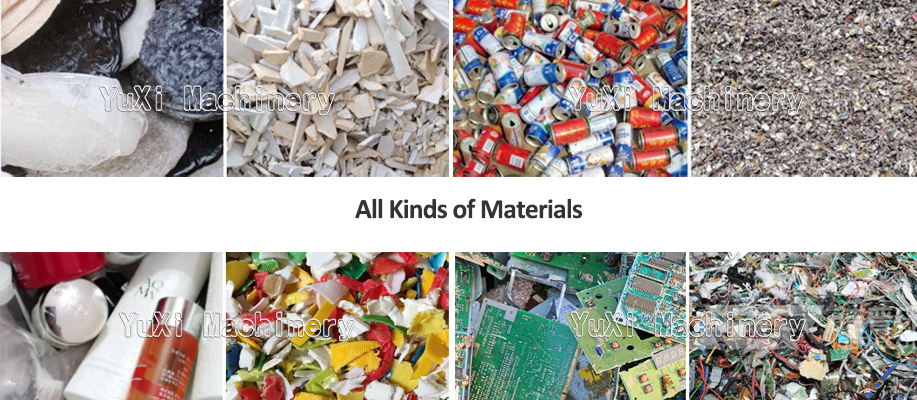

The double-shaft shredder is an industrial crushing equipment that uses double-shaft knife rollers rotating in opposite directions. It features low speed and high torque. This equipment can handle various types of waste such as metal, plastic, rubber and wood.

Application

The double shaft shredders (also called dual shaft shredder) are used for shredding the following materials:

- Metal: aluminum can bundle, steel drum, car shell, color steel tile, bicycle, copper aluminum radiator, oil filter, scrap wires, cables, aluminum composite plastic panel, steel wire rope, gas tank, zip-top can, engine case, paint bucket, etc.

- Plastic: plastic pallet, plastic drum, plastic bucket, plastic film, waste appliances shell, garbage plastic drum, IBC drum, IBC barrel,garbage bag, rubbish bag, plastic pipe, washing machine, forklift pallet, lead acid battery shell, etc.

- Textile: scrap clothes, shoes, fishing net, woven bag, ton bag, jumbo bag, fishing net bundles, dust collector bag, industrial textile waste, etc.

- Wood: wood furniture, wood pallet, scrap timber, sawdust chipboard, composite board, wooden door, forklift pallet, wood board, wood template, wooden case, etc.

- Paper: scrap paper and cartons, including scrap books, carton board, carton box, packaging box, waste newspaper, office paper, printing paper, paperboard, etc.

- Waste household appliances: TV, washing machine, refrigerator shell etc.

- Scrap tires: car tires, truck tires etc.

Working Principle

The shearing force is generated by the reverse rotation of two sets of independent knife shafts, and in combination with the fixed knife, a shearing gap is formed to achieve material shredding. The planetary reducer driven by dual motors provides power. During the meshing process of the knife teeth, tearing and squeezing effects occur. After multiple crushing, the material is discharged from the screen.

Feature

1.SKD11 features high toughness and crack resistance, maintaining the integrity of the blade even under high-intensity impact loads.

2.Planetary reducers operate by gear meshing, featuring small size, light weight, strong load capacity and long service life.

3.The knife shaft, which adopts high-precision rolling bearings and is processed with heavy-duty special steel, can withstand the impact force during high-load shredding operations, ensuring the stable operation of the equipment

4.Equipped with a PLC automatic control system and modular box design, it supports real-time monitoring of operating parameters such as bearing temperature and current load.

Parameter

| Models | Power (Kw) | Capacity | Materials size | Hopper size | Weight | Dimension |

| YXS-600 | 15*2KW | 2-3T/H | 3-10CM | 0.82*0.9M | 2.5T | 2.6*2*1.9M |

| YXS-800 | 22*2KW | 3-5T/H | 3-10CM | 0.9*1.0M | 3.6T | 2.8*2*1.9M |

| YXS-1000 | 37*2KW | 5-8T/H | 3-10CM | 1.2*1.0M | 5.7T | 3*2*1.9M |

| YXS-1200 | 45*2KW | 6-10T/H | 3-10CM | 1.4*1.0M | 9.5T | 3.2*2*1.9M |

| YXS-1400 | 55*2KW | 8-12T/H | 3-10CM | 2.0*2.0M | 18T | 4.3*2*2.4M |

| YXS-1600 | 75*2KW | 12-18T/H | 3-10CM | 2.3*2.0M | 24T | 5*3*2.4M |

| YXS-2000 | 90*2KW | 16-22T/H | 3-10CM | 2.3*2.0M | 35T | 6*3.5*2.4M |

| YXS-2200 | 132*2KW | 20-26T/H | 3-10CM | 2.5*1.8 | 62T | 7*4*4.5M |

| YXS-2600 | 160*2KW | 25-60T/H | 3-10CM | 3.2*2.0 | 85T | 8.2*4*4.3M |