Processed Materials:

Off-The-Road Tire

Truck tires

Car tires

Bicycle tires

Applications:

Tire recycling and processing center: As the first step in the production line, whole tires are shredded into rubber blocks that are easy to transport and process later.

On-site processing at ports and mines: Reduces the transportation and storage costs of giant tires, achieving on-site volume reduction and resource utilization.

Performance Advantages

The OTR tire cutting machine adopts automated technology, enabling it to quickly and continuously complete the cutting of giant tires.

The equipment uses a hydraulic system, and the blades are made of special wear-resistant alloy steel, which has high hardness and a long service life.

The equipment is equipped with automatic protective covers and emergency stop devices, effectively reducing operational risks and ensuring personnel safety.

Working Principle

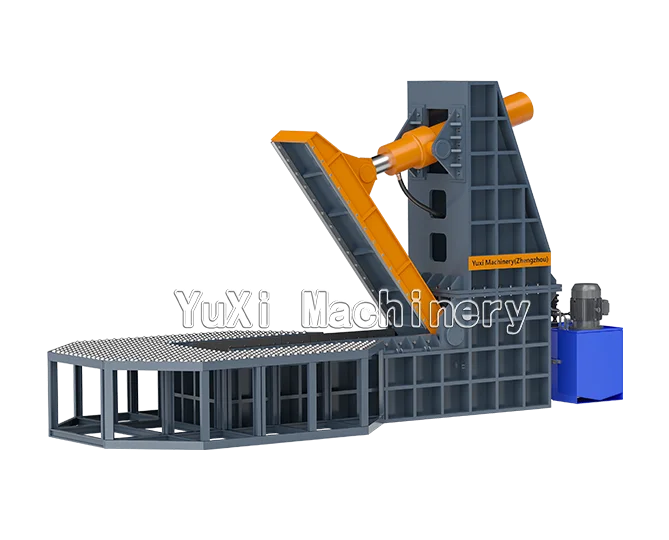

Feeding: The entire OTR tire is placed on the feeding platform or conveyor using a crane or heavy-duty forklift.

Feeding Positioning (Optional): The hydraulic pusher smoothly pushes the tire into the shearing chamber, ensuring the tire is in the optimal shearing position.

Core Shearing: Upon activation of the control system, high-pressure hydraulic oil drives the piston rod of the main shearing cylinder to extend forcefully, pushing the large moving blade parallel to the fixed blade. The two specially designed toothed blades interlock, generating a powerful shearing and tearing effect on the tire, completely cutting off the entire tire cross-section, including the sidewall, tread, and steel cords, in one pass.

Discharge and Reset: The sheared tire piece falls from the discharge port and is transported away by the conveyor below. The main shearing cylinder then automatically resets, ready for the next shearing operation.

Specifications

| Model | YX4000 |

| Process range | Diameter less than 4000mm(Including 4000mm) |

| Power (kw) | 18.5 kw |

| Size (mm) | 6200*1760*4590mm |

| Blade material | Cr12 |

| Blade number (Pieces) | 12 |

| Weight (kg) | 21000 |

| Hydraulic drive(Ton) | 300 |

| Feeding method | Mechanical lifting |

Related Case

LATEST EQUIPMENT

TIRE RECYCLING

OTR Tire

Truck Tire

Car Tire

Bicycle Tire

Rubber Tube

Other Rubber Product