Processed Materials:

Off-The-Road Tire

Truck tires

Car tires

Bicycle tires

Applications:

Fine Rubber Powder Production Line: Produces 40-120 mesh fine rubber powder for use in plastic running tracks.

Pre-treatment for reclaimed rubber production:: Grinding rubber blocks to a fineness suitable for desulfurization processes.

Preparation of modified rubber materials: Providing high-quality raw materials for rubber asphalt and rubber-plastic composites.

Performance Advantages

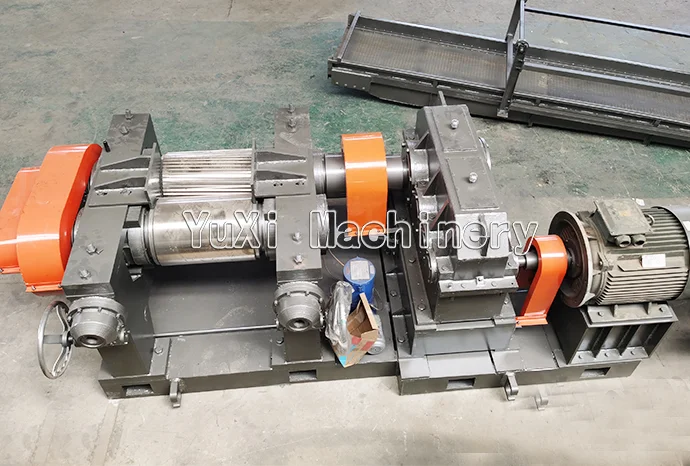

The gap between the two rollers can be precisely adjusted within the range of 0.1-5mm, ensuring uniform and stable output particle size.

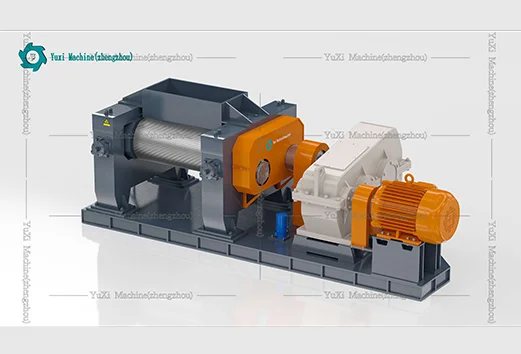

An innovative internal circulating water cooling system prevents rubber from aging and deteriorating due to high temperatures, maintaining the physicochemical properties of the rubber powder.

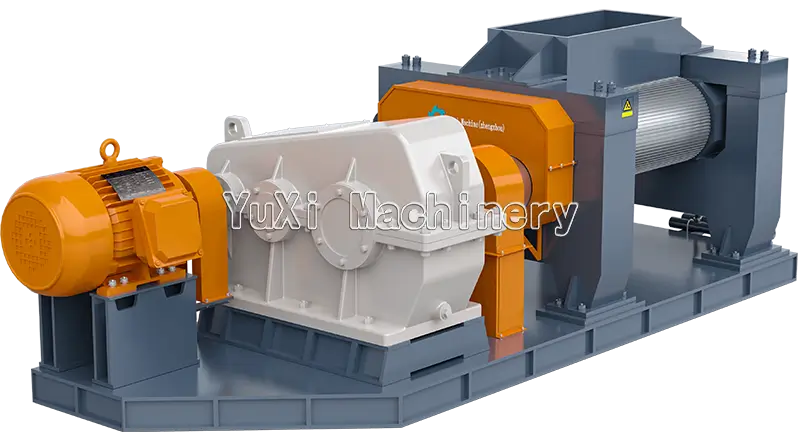

Equipped with an independent dual-motor drive system, each roller is directly driven by a high-power motor through a hardened gear reducer, resulting in high torque and high transmission efficiency.

The roller surface is made of special alloy chilled cast iron, with wear resistance 3-5 times that of ordinary materials, significantly extending maintenance cycles.

An integrated PLC control system with overload automatic protection and fault alarm functions allows for one-person operation of multiple machines.

Working Principle

Differential Shearing: The two rollers rotate relative to each other at different speeds (speed ratio 1:1.2-1:1.5), subjecting the material to intense shearing, compression, and tearing forces between the rollers.

Particle Size Control: The output particle size is precisely controlled by adjusting the gap between the two rollers to achieve the required fineness of the rubber powder.

Circulating Grinding: Coarse material is returned for re-grinding through an internal circulation system, ensuring a first-pass yield of over 85%.

Specifications

| Input rubber material size | <50mm |

| Power | 132kw+0.37kw |

| Diameter of front roll(mm) | 560(Groove) |

| Diameter of rear roll(mm) | 510(Smooth) |

| Working extrusion length | 870mm |

| Linear speed of front roller | 48.79 m/min |

| Linear speed of rear roller | 31.40 m/min |

| Roller line speed ratio | 1.55:1 |

Related Case

LATEST EQUIPMENT

TIRE RECYCLING

OTR Tire

Truck Tire

Car Tire

Bicycle Tire

Rubber Tube

Other Rubber Product