Processed Materials:

Off-The-Road Tire

Truck tires

Car tires

Bicycle tires

Applications:

Reclaimed Rubber Preparation: Provides uniformly fine raw material rubber powder for dynamic desulfurization processes.

Rubber Asphalt Modification: Produces specialized rubber powder for road asphalt modification.

Plastic Rubber Blending: Provides high-quality rubber fillers for plastic modification. Sports Field Materials: Produces specialized rubber powder for plastic running tracks and sports field surfaces.

Performance Advantages

Utilizes circulating water cooling to effectively protect the integrity of rubber molecular chains and maintain the physical properties of the rubber powder.

Equipped with a turbine-type airflow classifier, it enables simultaneous multi-stage particle size separation, resulting in uniform particle size distribution and a single-stage classification efficiency exceeding 95%.

Integrates a PLC + touchscreen intelligent control system that monitors and automatically adjusts grinding parameters in real time, featuring fault self-diagnosis and production data recording functions.

Optimized grinding chamber flow field design and equipped with a permanent magnet synchronous motor reduce energy consumption by 25-30% compared to traditional models, while increasing output by over 20%.

Built-in pulse bag dust collector system achieves a dust collection efficiency of 99.9%, with an ambient dust concentration below 5mg/m³.

Working Principle

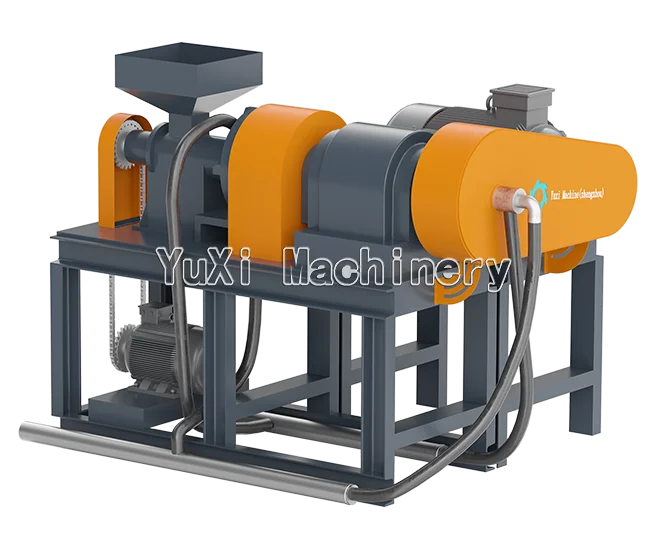

A rubber pulverizer includes a main pulverizing unit, a feeding mechanism, a water cooling system, a grading device, and a powder collector. Material is fed in evenly by the feeding mechanism, pulverized by the grinding discs, and the fine powder is separated by air or centrifugal force, while coarse particles are returned for reprocessing, achieving continuous production.

Specifications

| Motor Specifications | Electric-Siemens | Electric-Siemens | Electric-Siemens |

| Power | 30KW | 30KW*2 | 30KW*4 |

| Voltage | as per request | ||

| Equipment Dimensions L*W*H (mm) | 1350*650*1090 | 2410*650*1090 | 2410*1100*1090 |

| Equipment Weight | 1400Kg | 2600Kg | 5000Kg |

| Capacity | 100-150Kg/h | 200-300Kg/h | 400-600kg/hr |

| Final Product | 10-140 mesh | ||

Related Case

LATEST EQUIPMENT

TIRE RECYCLING

OTR Tire

Truck Tire

Car Tire

Bicycle Tire

Rubber Tube

Other Rubber Product