Processed Materials:

Off-The-Road Tire

Truck tires

Car tires

Bicycle tires

Applications:

Tire recycling plants: As the final finishing equipment for steel wire recycling, it converts tire bead rings into directly marketable steel wire commodities.

Steel wire processing enterprises: Providing high-quality, short-process recycled steel wire raw materials to wire drawing plants, nail manufacturing plants, and hardware manufacturers.

High-value resource recycling projects: Focusing on maximizing the metal value recovery from waste tires.

Performance Advantages

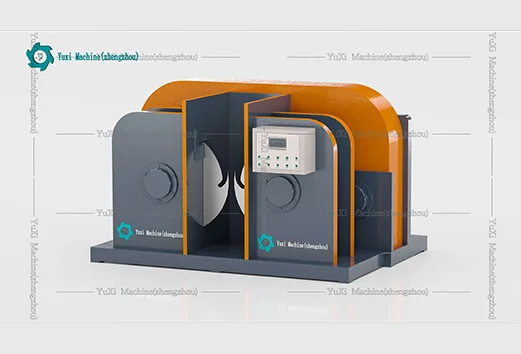

Utilizing a patented rotary cutting system with high-precision hydraulic control, it can complete the bead cutting of a giant tire within 3-5 minutes, achieving millimeter-level precision.

Equipped with a high-power hydraulic power unit, it outputs stable and powerful cutting force, easily handling even the toughest steel wire bead cutting, ensuring a smooth and uninterrupted cutting process.

Integrated PLC intelligent control system enables one-button operation, parameter memory, and fault self-diagnosis, significantly reducing operational difficulty and labor costs.

Multiple safety protection devices, including an emergency stop system, overload protection, and safety guards, ensure the safety of operators and equipment.

Key cutting components are made of imported high-strength alloy steel, undergoing a special heat treatment process, increasing wear resistance and service life by more than 3 times compared to ordinary materials.

Working Principle

Feeding and Positioning: The pre-treated tire bead is hoisted onto the equipment's dedicated feeding rack, and the steel wire end is manually guided into the traction mechanism.

Clamping and Traction: Hydraulic or pneumatic clamping rollers firmly clamp the steel wire end. Driven by the main drive wheel, the steel wire is pulled out of the tire bead at a uniform and stable speed.

Breaking and Peeling: Multiple sets of breaking blades and peeling rollers are set along the traction path. As the steel wire is pulled out, these devices peel and break off the remaining rubber and fiber covering the wire layer by layer.

Cleaning: The straightened and peeled steel wire passes through high-pressure air nozzles and rotating cleaning brushes to remove fine rubber particles and dust adhering to the surface, resulting in bright steel wire.

Finished Product Unloading: When the steel wire roll reaches the set weight or diameter, the equipment automatically or prompts a stop, unloading the finished roll.

Specifications

| Model | YX-1200 |

| Input Tires | ≤1200mm |

| Capacity | 100-120 Tires / Hour Output |

| Output Tires | Whole Tyre And Tyre Rim Steel |

| Motor | Siemens |

Related Case

LATEST EQUIPMENT

TIRE RECYCLING

OTR Tire

Truck Tire

Car Tire

Bicycle Tire

Rubber Tube

Other Rubber Product