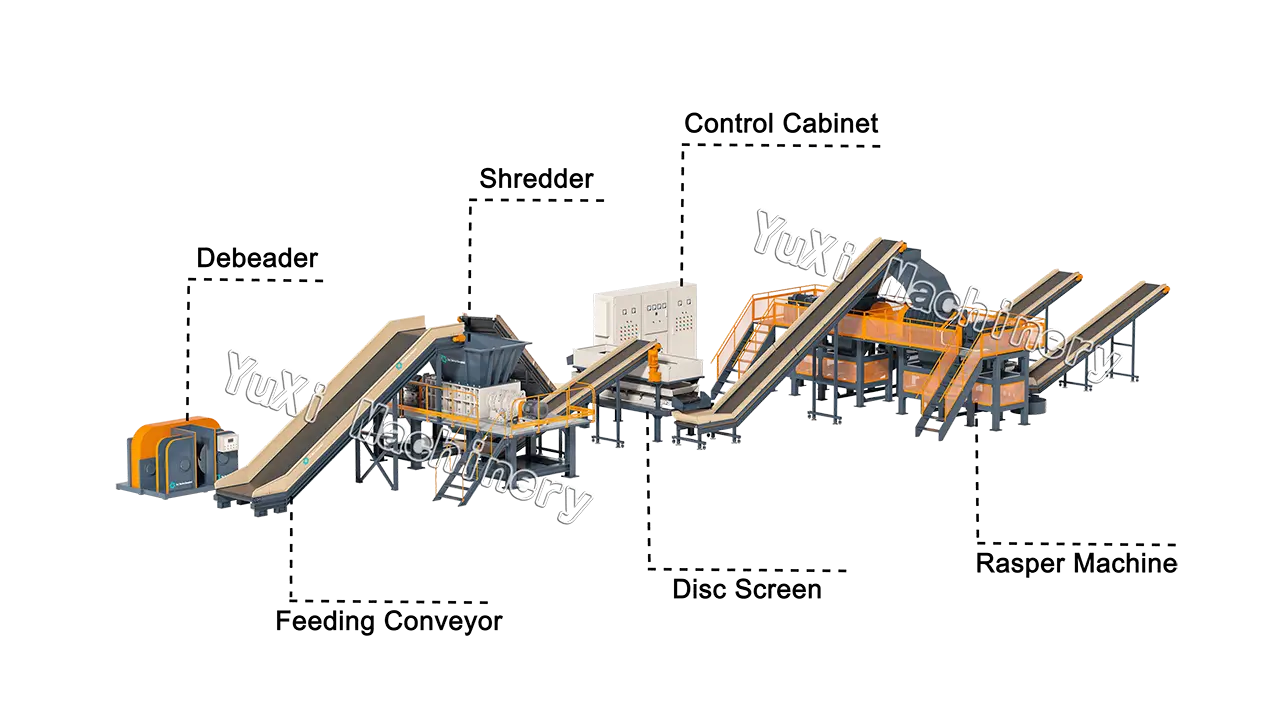

Free wire rubber mulch, are recycled rubber products obtained through the mechanized processing of waste tires. Their particle size typically ranges from 10-50 mm. Compared to fine rubber powder, the production process of large rubber granules prioritizes high efficiency and energy saving, while also meeting the needs of more applications requiring high physical properties of rubber. This makes it an economical and efficient method for recycling waste tires.