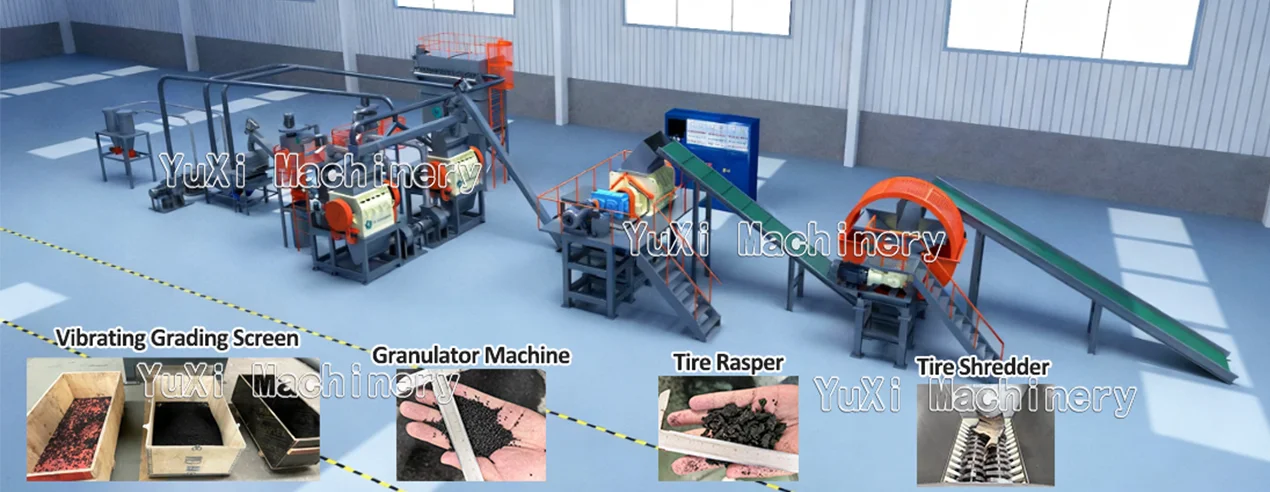

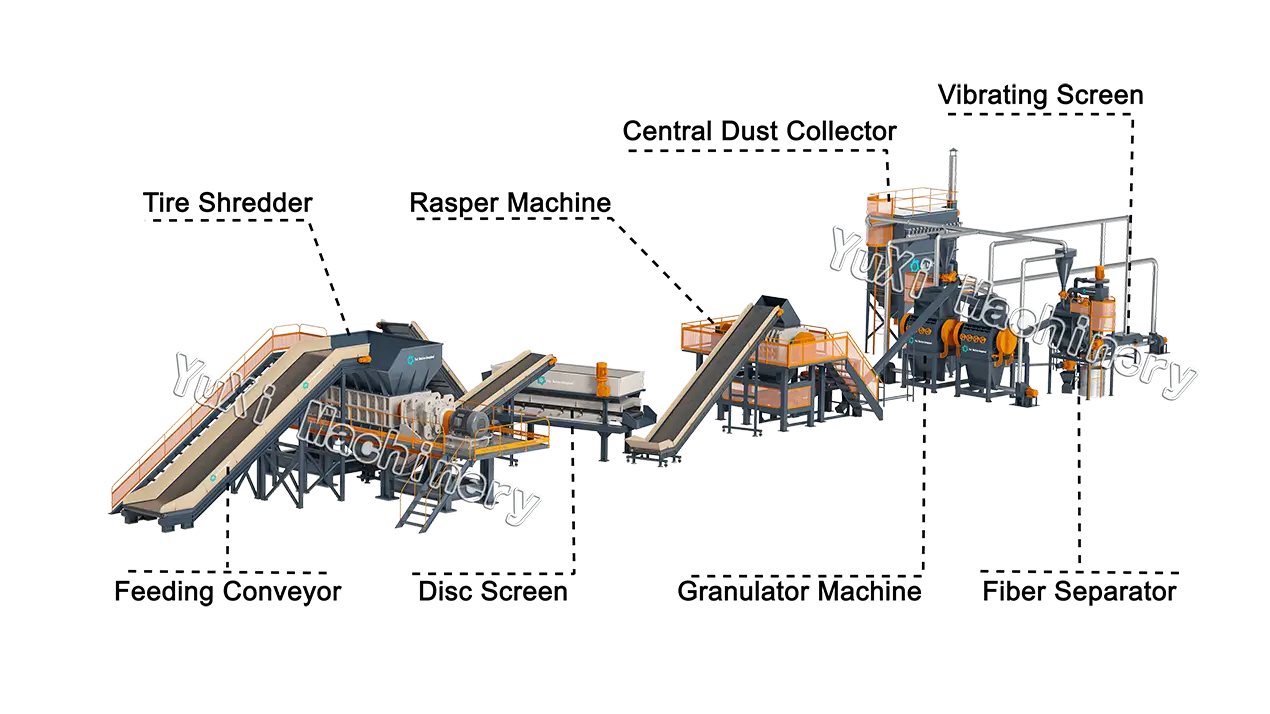

Crumb Rubber are a recycled resource product obtained through multi-stage physical processing of waste tires. It efficiently separates the rubber component from other materials (steel wire, fiber) in waste tires, ultimately processing it into granular materials of different mesh sizes. These recycled rubber granules retain the excellent properties of both natural and synthetic rubber, such as elasticity, abrasion resistance, and aging resistance. They are a high-value-added environmentally friendly material widely used in various industrial sectors and daily life.