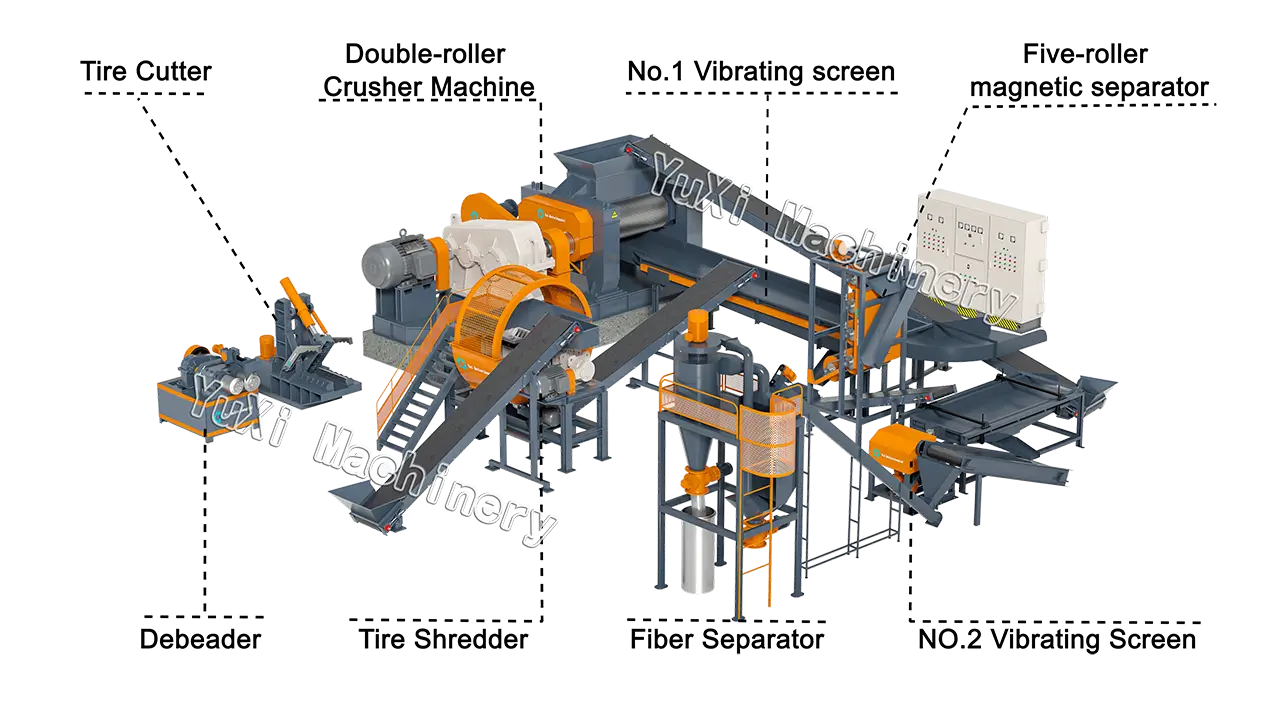

Stage 1: Raw Material Pre-treatment

After sorting and classification, waste tires are fed into a wire removal machine to efficiently remove the bead wires. The pre-treated tires then enter tire shredder, where they are crushed into coarse blocks of 50-100mm, preparing them for subsequent fine processing.

Stage 2: Roller Precision Crushing

The coarsely crushed tire blocks enter the core equipment—the roller-type rubber crusher. Through two specially designed rollers rotating in opposite directions, the material is processed into rubber granules of the target particle size under the combined effects of compression, shearing, and grinding. By adjusting the roller spacing, granular products of different specifications from 1-10mm can be flexibly produced.

Stage 3: Grading and Purification

The crushed material is passed through magnetic separator to remove residual metal impurities, ensuring product purity. It then enters grading and screening system to achieve precise separation of granules and powder, and multi-stage screening can be performed as needed to meet the specifications of different customers.

Stage 4: Environmental Collection

The entire process is equipped with a dust removal system to effectively collect dust generated during production. This ensures a clean production environment and also collects high-value-added fine rubber powder.