Processed Materials:

-

Bentonite grinding and processing

-

POP and gypsum board plant

-

Quartz Stone Grinding Mill

-

Dolomite Grinding Mill

Applications:

limestone desulfurization in power plant, heavy calcium carbonate processing, non-metallic mineral powder making, solid fuel grinding, building materials and chemical industry.

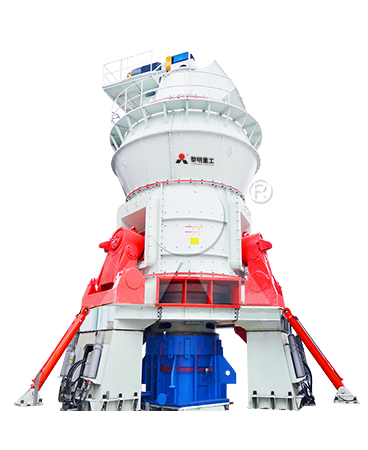

Capacity: 3-55TPH

Input size: 30-50mm

Performance Advantages

Mature technology and stable Performance: 4th generation mill, more than 30 years of mill manufacturing experience. Bevel gear overall drive provides strong power. the production capacity increased by 20% under the same power condition.

Economical and reliable: can grind a variety of minerals to meet the needs of different specifications of particle size; low investment cost, low operating cost, single machine processing capacity up to 60T/H.

Low cost, less maintenance: Patented technology, with Inner automatic thin-oil lubricating system, long oil change cycle, low frequency, low cost.

Scientific allocation, low energy consumption: Adjustable output size, efficient powder production. The vulnerable parts adopt special technology and material, more wear-resistant.

Environmental protection: unique air recycling system, together with advanced dust collector make environment much cleaner.

The waste tire recycling production line is an equipment system that converts waste tires into recyclable resources such as rubber particles and rubber powder through physical and mechanical processing, with dual environmental and economic benefits.

Application

1.Rubber Product Recycling

Rubber powder can replace virgin rubber in the production of tires, hoses, rubber pads, and other products, reducing the demand for virgin rubber.

2.Asphalt Modification

Adding rubber powder to asphalt can improve road performance, extend service life, and is widely used in highway construction.

3.Waterproof Materials and Building Materials

It can be made into waterproof coatings, rubber floor tiles, or runway materials for use in buildings, gardens, and other scenes.

4.Industrial Raw Materials

Steel wire can be recycled for metal processing, and fiber materials can be used to produce soundproof cotton, insulation materials, etc.

Working Process

1.Tyre Wire Drawing Machine: removes tire steel rings.

2.Tire Shredder: shreds waste tires into blocks for subsequent processing.

3.Steel Wire Separator: Separate rubber and steel wire through mechanical extrusion to recover metal resources.

4.Rubber Pellet Machine: Crush rubber blocks into 1-7mm pellets.

5.Magnetic Separator: removes impurities and recovers metal components (such as steel wire).

6.Grinder Mill:Grind rubber particles into 5-80 mesh rubber powder

7.Dust Removal System: Reduce dust pollution through wind and water cooling and spraying devices.

8.Automatic Bagging System:The processed rubber particles or powder are quantitatively packed into packaging bags

Feature

1.Automation and Intelligence

Modern production lines adopt PLC control systems to achieve automated operations

2.Environmental Protection and Energy Conservation

Equipped with a closed dust removal system and water cooling system, dust and smoke emissions meet environmental standards. The equipment has low energy consumption, stable operation, and meets the requirements of green and low-carbon.

3.Efficient and Flexible

Support customized production volume. Adopting modular design, easy installation and maintenance